- Ultra High Purity (NH₃)

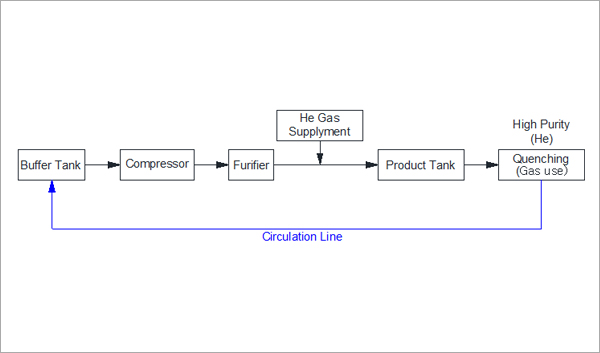

- He recycle system

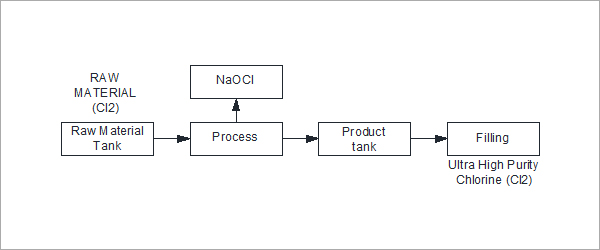

- Ultra High Purity Chlorine (Cl₂)

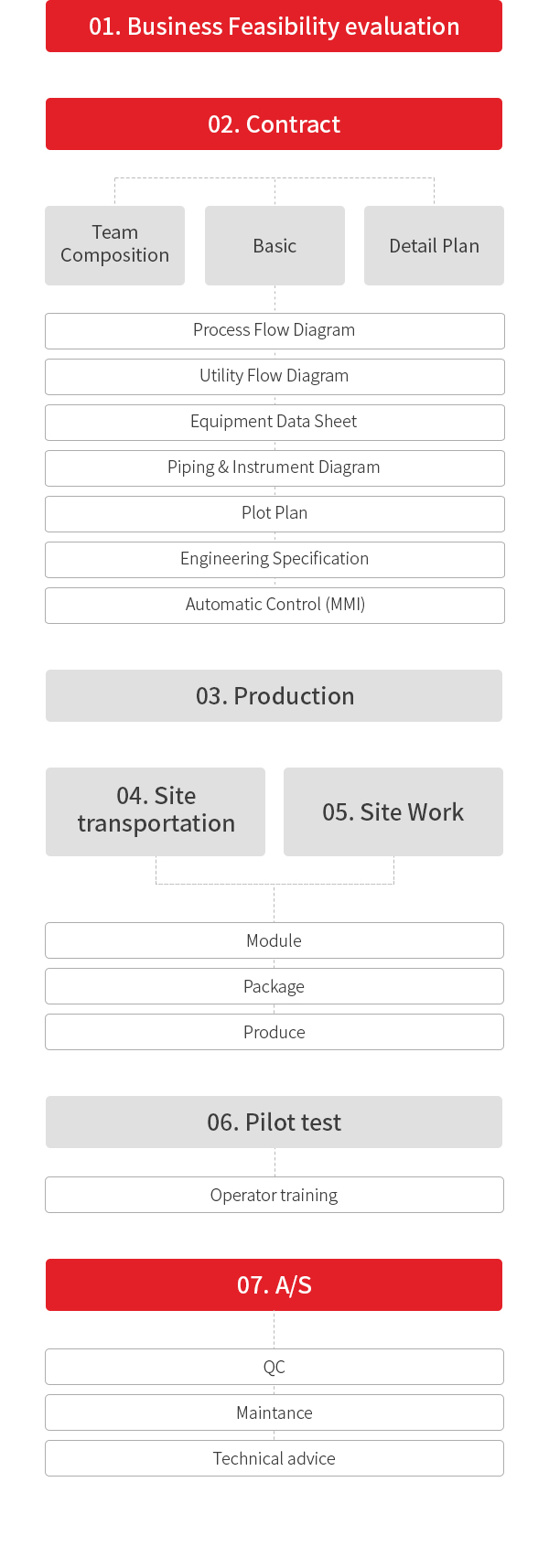

- Plant Flow Chart

Ultra High Purity (NH₃)

Coretech’s own technical capability will carry out the construction

of a contract, including business feasibility evaluation, plant design (including simulation), production, supply, installation and pilot test.

-

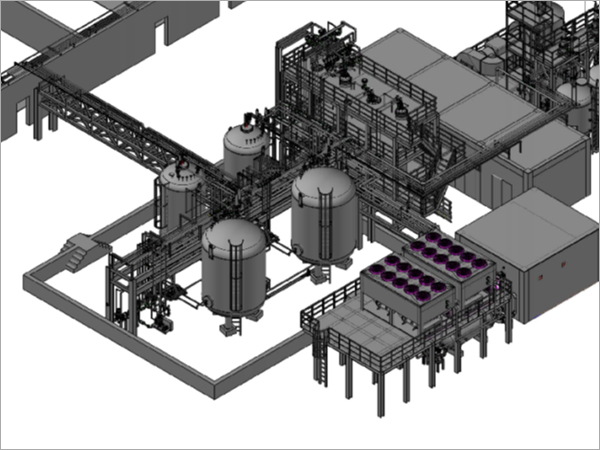

Plant specification

- - Capacity

- 5,000Ton/year

- - Quality

-

Input NH₃ 99.6%over, Residual : 0.4%

(Raw NH₃ residual : H₂O, Oil, O₂, N₂, CO, CO₂, CnHm…)

Output : 7N NH₃

-

Human Safety First

Advantages of Automated Systems

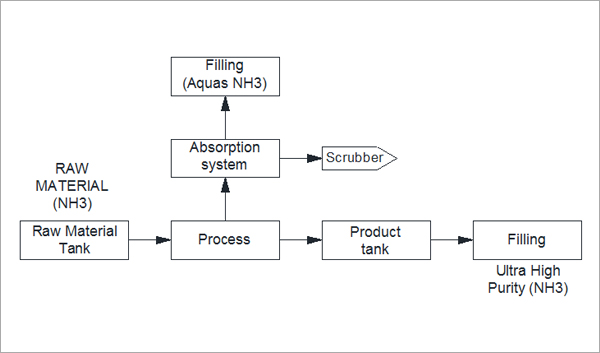

Mechanical advantage- - Produce ultra-high purity NH3 gas which used in semiconductor,

LED and heat treatment process. - - Raw Material 99.6% -> Product 99.99999%(7N) 97% yield,

90% operation ratio. - - Resell VENT GAS as industrial ammonia water to maximize profit and reduce sewage treatment costs.

- - Reduce plant construction costs based on simple production and maximize production capacity.

- - Produce ultra-high purity NH3 gas which used in semiconductor,

-

Performance

- Domestic

-

- Pyungtaek Company “C” High Purity Gas Production Plant 1,000 MT per year

- Ansan Company “S” High Purity Gas Production Plant 500 MT per year

- Ansung Company “C” High Purity Gas Production Plant 5,000 MT per year

- Gumi Company “A” High Purity Gas Production Plant

- Ansan Company “O” High Purity Gas Production Plant

- Youngin Company “O” High Purity Gas Production Plant

- Ansan Company “S” High Purity Gas Production Plant 1,000 MT per year

- Gumi Company “J” High Purity Gas Production Plant 500 MT per year - Aboard

- - China Company “A” High Purity Gas Production Plant 4,000 MT per year

- Ultra-high purity ammonia is a special gas for industrial processes such as ultra-thin liquid crystal displays (TFT-LCDs), integrated circuits and light-emitting diodes (LEDs).

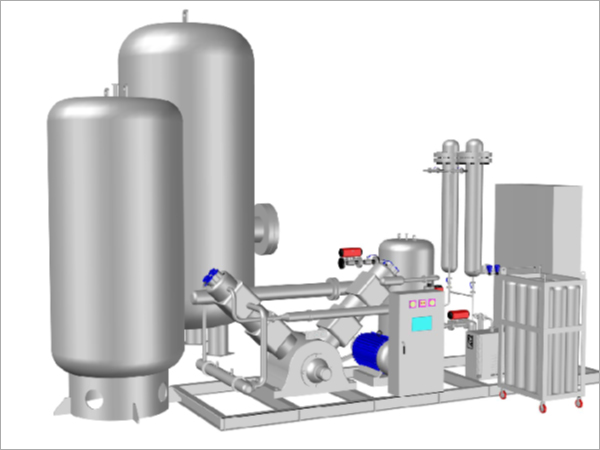

He recycle system(Package)

Based on Coretech’s technology, recollects and recycles Helium which

used in semiconductor and heat treatment process to reuse.

-

Human Safety First

Advantages of Automated Systems

Mechanical advantage- - After refine 99.9%(3N) He to 99.999(5N) O2 ratio under 20ppm, recollects and reuses

- - In catalyst base, convert O2 which produce in a process recovery to H2O with H2 chemical reaction and emit dryer

(He)=>Catalyst+(H2+O2)=H2O - - Through Helium recycling system, use of quench medium

(99.5% recovery per quench cycle) and cost savings

Ultra High Purity Chlorine (Cl₂)

-

Mechanical advantage

- - Produce ultra-high purity Cl₂ gas which used in semiconductor, LED and heat treatment process

- - Raw Material 99.5% -> Product 99.9999%(6N) 97% yield, 90% operation ratio

- - Low operation costs due to automatic system

- - Reduce plant construction costs based on simple production and maximize production capacity

-

Performance

- - Ansung Company “C”

- High Purity Gas Production Plant 1,000 MT per year

- - Ulsan Company “H”

- High Purity Gas Production Plant 1,000 MT per year

-

Plant specification

- - Capacity

- 5,000Ton/year

- - Quality

-

Input NH₃ 99.6% over, Residual : 0.4%

(Raw NH₃ residual : H₂O, Oil, O₂, N₂, CO, CO₂, CnHm)

Output 7N NH₃

-

Human Safety First

Advantages of Automated Systems

Plant Flow Chart